Inverse Kinematics

Imagine a robot arm reaching out to grab an object. Simple, right? Not quite. The process behind that smooth movement is far more complex than it seems. In fact, it involves a mathematical puzzle that’s been quietly powering robotics for decades—one that most people outside the field have never even heard of: inverse kinematics.

By Tomás Oliveira

So, what exactly is inverse kinematics (IK)? In simple terms, it's the process of determining the angles and positions of a robot's joints to achieve a desired end position. Think of it like this: you know where you want the robot's hand to be, but now you need to figure out how to move its arm, elbow, and shoulder to make that happen. It’s a bit like solving a puzzle where the final image is already known, but you have to figure out how to arrange the pieces to get there.

But why is this concept so crucial to robotics? Well, without IK, robots would be clumsy, inefficient, and, frankly, useless in most real-world applications. Whether it’s a robotic arm in a factory assembling cars or a humanoid robot performing delicate surgeries, inverse kinematics ensures that every movement is precise, smooth, and, most importantly, achievable. It’s the unsung hero of robotics, quietly working behind the scenes to make sure robots don’t just flail around like confused toddlers.

The Math Behind the Magic

Alright, I know what you're thinking: “Math? Really?” But bear with me—this is where things get interesting. Inverse kinematics is essentially a mathematical problem that involves solving a set of equations. These equations relate the position of the robot’s joints (its angles) to the position of its end effector (the hand, gripper, or tool at the end of the robot’s arm).

For example, imagine you want a robotic arm to pick up a cup from a table. You know where the cup is, but the robot doesn’t. The IK algorithm takes the cup’s position and calculates how each joint in the robot’s arm needs to move to get the gripper to the cup. It’s like reverse-engineering the movement. Instead of starting with the joint angles and figuring out where the hand will end up, you start with the hand’s desired position and work backward to figure out the joint angles.

But here’s the catch: there’s usually more than one solution to the problem. In fact, there can be an infinite number of solutions. For example, if you ask a human to reach for a cup, they could do it in a variety of ways—by bending their elbow more, or less, or by rotating their shoulder differently. Robots face the same dilemma, and that’s where things get tricky. The IK algorithm has to choose the best solution based on factors like efficiency, speed, and avoiding obstacles.

Forward vs. Inverse Kinematics

At this point, you might be wondering: “Wait, if there’s inverse kinematics, is there a regular kinematics?” You bet there is! It’s called forward kinematics (FK), and it’s essentially the opposite of IK. In forward kinematics, you know the angles of the robot’s joints, and you calculate where the end effector will be. It’s like saying, “If I bend my elbow this much and rotate my shoulder that much, my hand will end up here.”

Forward kinematics is easier to compute, but it’s not as useful in real-world applications. Why? Because in most cases, you don’t care about the joint angles—you care about where the robot’s hand (or gripper, or tool) ends up. That’s why inverse kinematics is so much more important in robotics. It’s all about figuring out how to get the robot to do what you want, not just predicting where it will go if you move its joints a certain way.

Applications of Inverse Kinematics

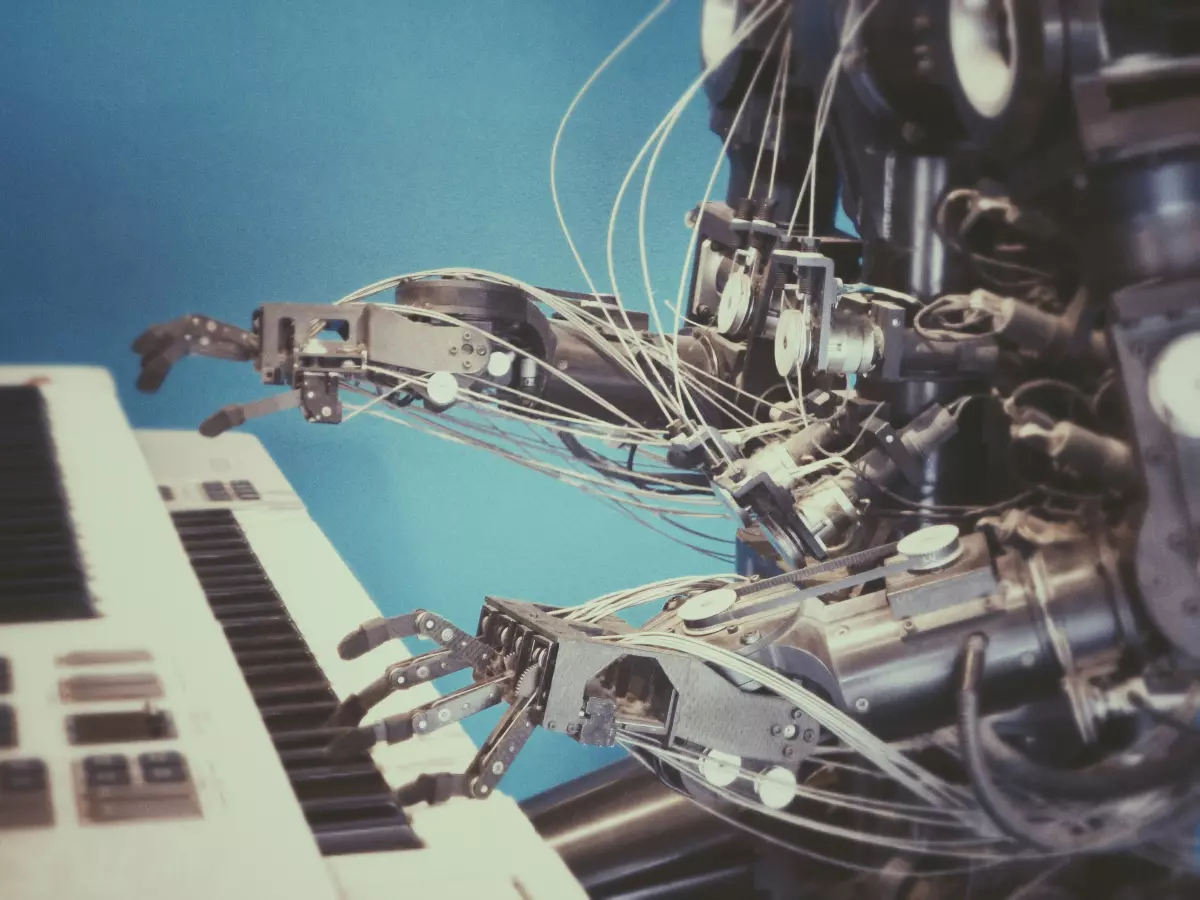

Now that we’ve covered the basics, let’s talk about where inverse kinematics really shines. One of the most common applications is in robotic arms, like the ones you see in manufacturing plants. These arms need to move with incredible precision to assemble cars, electronics, and other products. Without IK, these robots would be slow, clumsy, and prone to errors.

But it’s not just factory robots that rely on IK. Humanoid robots, like those used in healthcare or customer service, also need IK to perform tasks like shaking hands, picking up objects, or even walking. Yes, walking! Inverse kinematics is crucial for getting a robot’s legs to move in a coordinated way that mimics human walking. Without it, robots would stumble around like they’ve had one too many drinks.

Another fascinating application of IK is in animation and video games. Ever wonder how characters in games move so smoothly? Yup, inverse kinematics. Game developers use IK algorithms to make sure characters’ limbs move naturally, whether they’re running, jumping, or swinging a sword. It’s the secret sauce behind those fluid animations that make games feel so immersive.

The Challenges of Inverse Kinematics

Of course, like anything in robotics, inverse kinematics isn’t without its challenges. One of the biggest issues is something called the “singularity problem.” This happens when the robot’s joints align in such a way that the IK algorithm can’t find a solution. It’s like trying to solve a puzzle where some of the pieces are missing. When this happens, the robot can freeze up or make erratic movements, which is obviously not ideal if it’s, say, performing surgery or assembling a car.

Another challenge is computational complexity. Calculating IK solutions can be time-consuming, especially for robots with many joints, like humanoids or multi-limbed robots. In real-time applications, like gaming or surgery, the IK algorithm needs to work fast, which means developers have to find ways to optimize the calculations without sacrificing accuracy.

Conclusion: The Unsung Hero

So, there you have it. Inverse kinematics might not get as much attention as AI or machine learning, but it’s just as important—if not more so—in making robots useful in the real world. Whether it’s assembling cars, performing surgery, or just walking down the street, IK is the hidden force that makes it all possible. So next time you see a robot moving with precision and grace, remember: it’s not magic—it’s math.