Robot Joints Demystified

Ever wondered how robots move with such precision and grace? It's all about their joints—let's break it down and uncover the magic behind the motion.

By Sophia Rossi

Robots are no longer just clunky machines with stiff movements. Modern robotics has evolved to mimic human-like flexibility and precision, and at the heart of this transformation lies the humble yet ingenious robot joint mechanism. From industrial arms assembling cars to humanoid robots shaking hands, joints are the unsung heroes of robotic motion.

But what exactly are robot joints, and why are they so crucial? In simple terms, joints are the connection points that allow different parts of a robot to move relative to each other. Think of them as the robotic equivalent of your elbows, knees, or wrists. Without them, robots would be nothing more than static sculptures.

Types of Robot Joints

Robot joints come in various flavors, each designed for specific tasks and movement patterns. Here are the most common types:

- Revolute Joints: These allow rotational movement around a single axis, much like a door hinge. They're the most common type of joint in robotics.

- Prismatic Joints: These enable linear movement along a single axis, similar to the motion of a sliding drawer.

- Spherical Joints: These offer rotational movement around multiple axes, akin to a ball-and-socket joint in the human body.

- Cylindrical Joints: A combination of rotational and linear movement, perfect for tasks requiring both types of motion.

- Planar Joints: These allow movement in a two-dimensional plane, ideal for flat surfaces.

The Science Behind the Motion

So, how do these joints actually work? The magic lies in a combination of mechanical design, control systems, and software. Here's a quick breakdown:

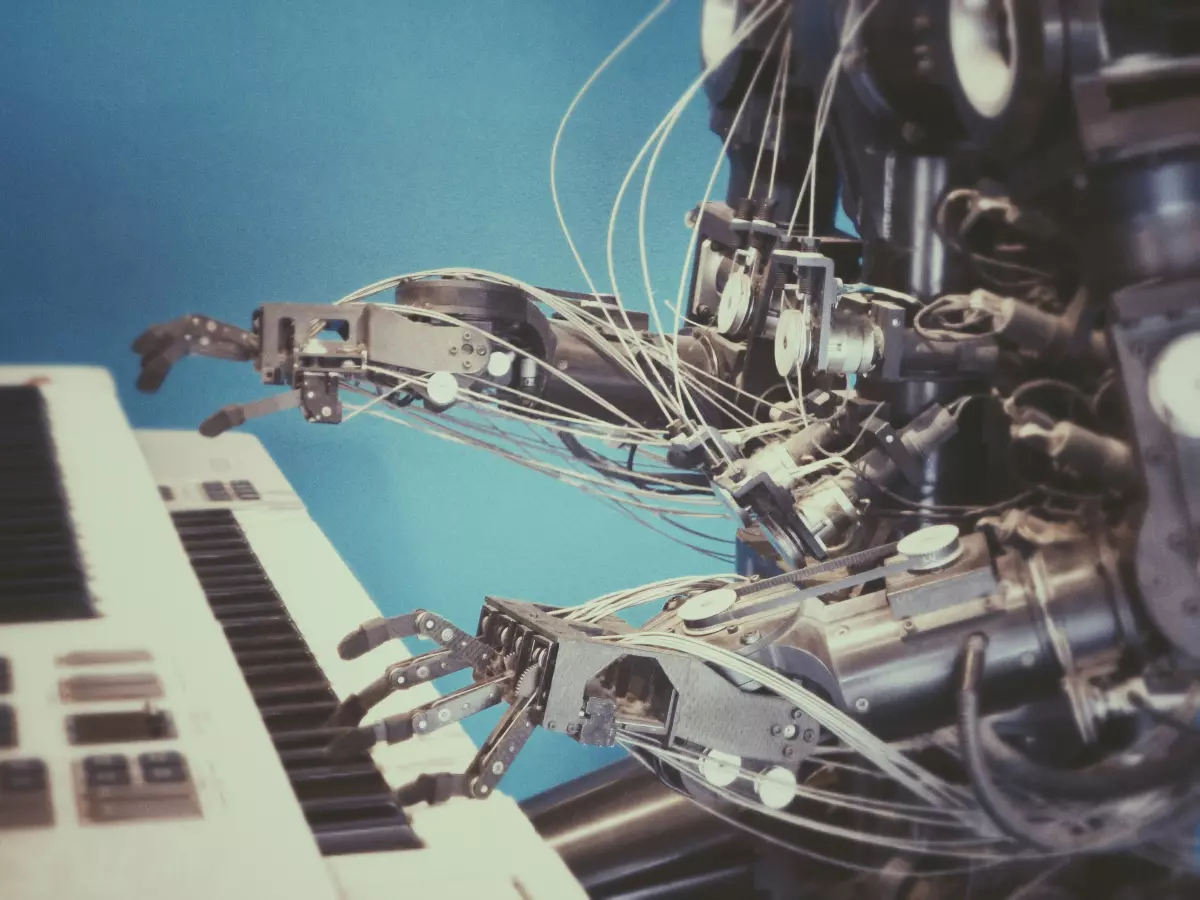

- Actuators: These are the muscles of the robot, providing the force needed for movement. Common types include electric motors, hydraulic systems, and pneumatic systems.

- Sensors: To move precisely, robots rely on sensors to provide real-time feedback on position, speed, and force.

- Control Systems: These are the brains behind the operation, processing sensor data and sending commands to the actuators.

- Software: Advanced algorithms calculate the optimal way to move, ensuring efficiency and accuracy.

Applications and Challenges

Robot joints are used in a wide range of applications, from industrial automation to healthcare and even space exploration. For instance, robotic arms with revolute joints are commonly used in manufacturing to assemble products with high precision. Meanwhile, humanoid robots with spherical joints are being developed to assist in caregiving and other human-centric tasks.

However, designing and implementing robot joints is not without its challenges. Engineers must consider factors like load capacity, range of motion, and durability. Additionally, achieving a balance between flexibility and strength is a constant struggle. And let's not forget the cost—high-performance joints can be expensive to produce and maintain.

The Future of Robot Joints

As robotics technology continues to advance, so too will the design and functionality of robot joints. Researchers are exploring new materials like lightweight composites and smart materials that can change shape in response to stimuli. There's also growing interest in bio-inspired designs, such as joints that mimic the complex movements of human muscles and tendons.

Moreover, the integration of artificial intelligence is set to revolutionize how robot joints operate. Imagine a robot that can adapt its movements in real-time based on its environment, becoming more efficient and versatile with each task.

In conclusion, robot joints may not be the flashiest aspect of robotics, but they are undoubtedly one of the most critical. The next time you see a robot in action, take a moment to appreciate the intricate mechanisms that make its movements possible. After all, it's the little things—like joints—that make big things happen.