Inside Robotics

Robots are more than just machines—they're systems of systems. But what really makes them tick? It's not just AI or hardware; it's the control systems that bring everything together.

By Nina Schmidt

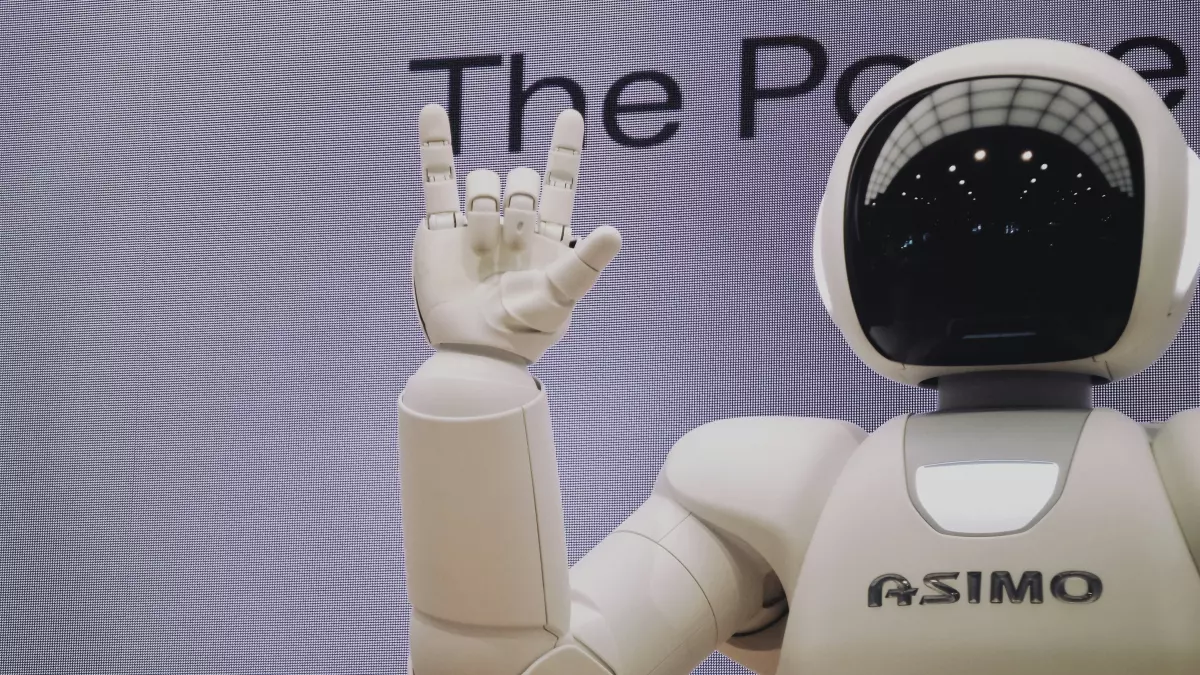

When we think of robots, we often picture humanoid machines walking around, or perhaps industrial arms assembling cars with precision. But what really makes these robots function? It’s not just the hardware or the AI algorithms running in the background. The real magic happens in the control systems that coordinate everything. These systems are like the nervous system of a robot, ensuring that every part works in harmony.

In this article, we’ll break down the five key components of modern robotics control systems. Whether you’re a robotics enthusiast or just curious about how these machines work, this guide will give you a deeper understanding of the tech behind the bots.

1. Sensors: The Robot's Eyes and Ears

Let’s start with the sensory input. Just like humans rely on their senses to interact with the world, robots need sensors to gather information about their environment. These sensors can detect everything from distance and temperature to light and sound.

For example, LiDAR sensors help autonomous vehicles 'see' their surroundings by bouncing light off objects and measuring the time it takes to return. Meanwhile, force sensors allow robotic arms to apply just the right amount of pressure when picking up delicate objects. Without sensors, robots would be blind and deaf, unable to respond to changes in their environment.

2. Actuators: The Muscles of the Machine

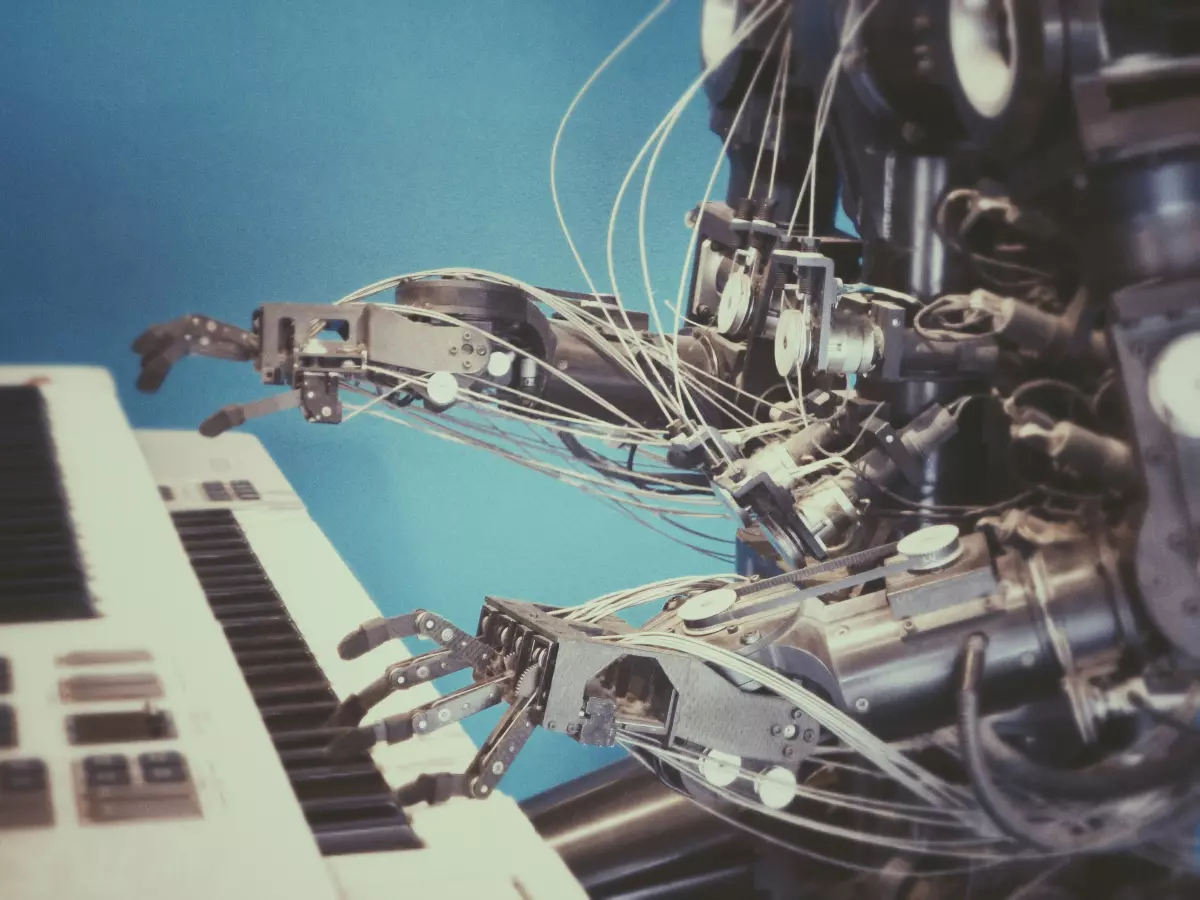

If sensors are the eyes and ears, actuators are the muscles. Actuators are responsible for converting electrical signals into physical movement. These can be motors, hydraulic systems, or even pneumatic systems, depending on the type of robot.

For instance, in a robotic arm, actuators control the joints, allowing the arm to move in different directions. In humanoid robots, actuators are responsible for walking, bending, and even facial expressions. The type of actuator used can significantly impact a robot’s speed, precision, and strength.

3. Controllers: The Robot's Brain

Now we get to the brains of the operation—the controllers. Controllers process the data from sensors and send commands to the actuators. Think of them as the robot’s decision-makers. They take in information, process it, and decide how the robot should respond.

Controllers can range from simple microcontrollers to more complex systems running advanced algorithms. In autonomous robots, these controllers often work in tandem with AI software to make real-time decisions. For example, a robot vacuum’s controller processes data from its sensors to avoid obstacles and clean efficiently.

4. Power Supply: The Robot's Heart

Every robot needs a power source to function. This could be batteries, fuel cells, or even solar power, depending on the application. The power supply is crucial because it determines how long a robot can operate and how much energy it has to perform tasks.

For example, drones rely on lightweight batteries to stay airborne, while industrial robots may use more robust power sources to handle heavy-duty tasks. The power supply also affects the robot’s mobility and range, especially in autonomous systems that need to operate for extended periods without human intervention.

5. Communication Systems: The Robot's Voice

Finally, we have the communication systems. These allow robots to send and receive data, either with other machines or with human operators. Communication systems can range from simple wired connections to complex wireless networks.

In autonomous robots, communication is essential for coordinating with other machines or receiving updates from a central control system. For example, in a warehouse full of autonomous robots, communication systems ensure that each robot knows where to go and what to do without crashing into each other.

In some cases, robots even communicate with humans through natural language processing, allowing for voice commands or even conversations. This is especially important in service robots that interact directly with people.

Bringing It All Together

So, what happens when you combine sensors, actuators, controllers, power supplies, and communication systems? You get a fully functioning robot capable of performing complex tasks autonomously. Each component plays a vital role, and without one, the entire system would fall apart.

While AI and machine learning often steal the spotlight, it’s these control systems that form the backbone of modern robotics. They ensure that robots can not only think but also act in the real world. And as technology continues to advance, we can expect these systems to become even more sophisticated, enabling robots to take on increasingly complex roles in our lives.

So next time you see a robot in action, remember—it’s not just the software or the hardware that’s making it work. It’s the intricate dance of control systems working behind the scenes.