Precision Showdown

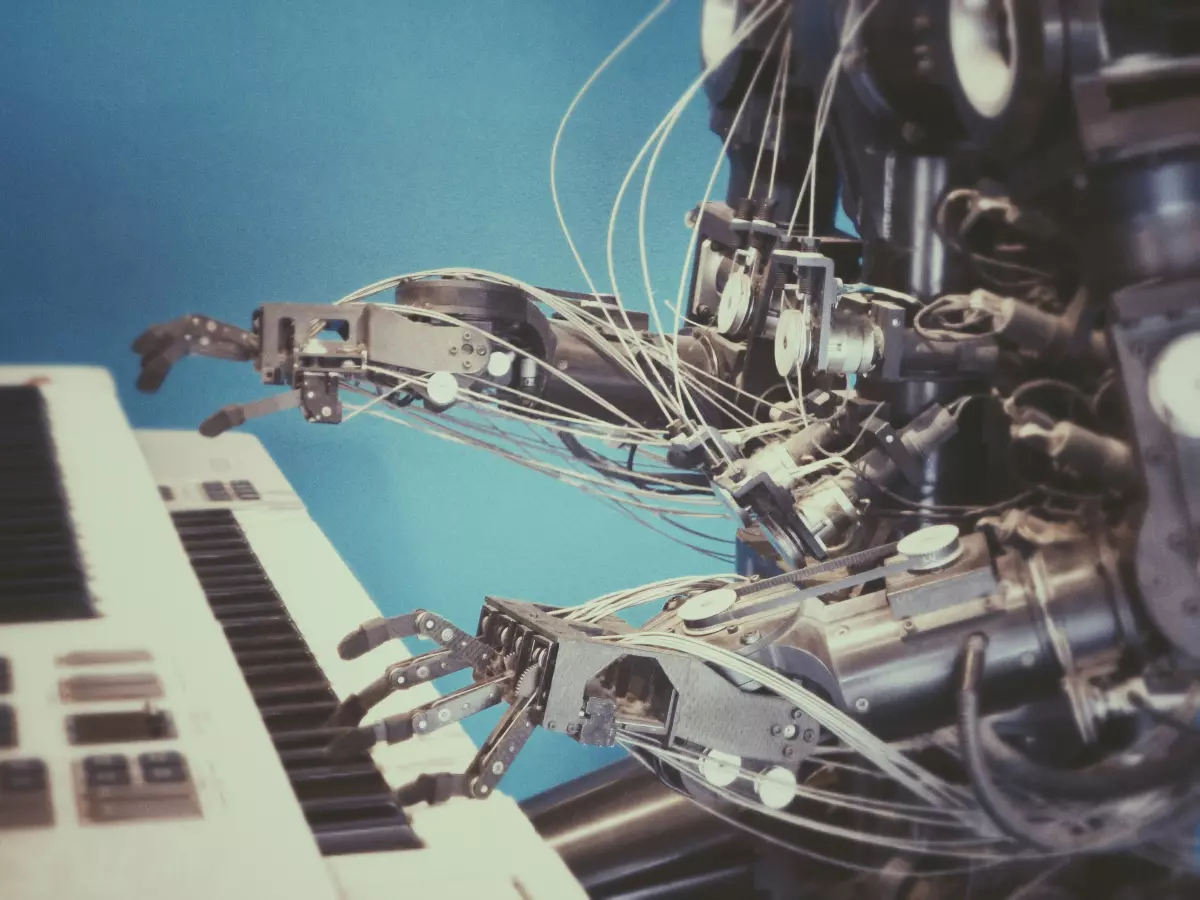

The robot's arm hovered, just a fraction of an inch above the delicate glass surface. It needed to place the object down with absolute precision. One wrong move, and the entire operation would be ruined. The sensors were feeding data to the control system, but the actuators were the ones making the final call. Which one was really responsible for this delicate dance of precision?

By Marcus Liu

In the world of robotics, precision isn't just a nice-to-have; it's a must-have. Whether it's a robot surgeon performing a life-saving operation or a manufacturing arm assembling the latest smartphone, the margin for error is razor-thin. But what really drives this precision? Is it the sensors, constantly feeding data to the robot's brain? Or is it the actuators, the muscles of the machine, that execute the final movements?

Let's break it down. Sensors and actuators are like the yin and yang of robotics. They work together, but they have very different roles. Sensors are the eyes and ears of the robot. They gather information from the environment—like distance, temperature, or pressure—and send it to the control system. The control system then processes this data and decides what the robot should do next. But here's the kicker: the sensors don't actually make the robot move. That's where actuators come in.

Sensors: The Data Whisperers

Sensors are the unsung heroes of precision. Without them, robots would be blind, deaf, and completely unaware of their surroundings. Think about it: how would a robot know how far away an object is without a distance sensor? How would it know how much pressure to apply without a force sensor? Sensors provide the critical feedback that allows robots to make informed decisions.

There are many types of sensors, each designed to measure different things. For example, proximity sensors help robots detect nearby objects, while gyroscopes help them maintain balance. Force sensors are crucial for tasks that require a delicate touch, like handling fragile objects. But no matter what type of sensor we're talking about, they all have one thing in common: they provide data, but they don't take action.

In fact, sensors are only as good as the control system that processes their data. If the control system isn't up to snuff, even the most advanced sensors won't make a difference. It's like having a high-end camera but using it with a blurry lens. The data is there, but it's not being used effectively.

Actuators: The Muscle Behind the Movement

While sensors are busy gathering data, actuators are the ones doing the heavy lifting—literally. Actuators are the components that make the robot move. They're responsible for translating the control system's decisions into physical actions. In other words, if sensors are the eyes and ears, actuators are the muscles.

There are several types of actuators, including electric motors, hydraulic actuators, and pneumatic actuators. Each type has its strengths and weaknesses. For example, electric motors are great for precise, controlled movements, while hydraulic actuators are better for tasks that require a lot of force. But no matter what type of actuator a robot uses, its job is the same: to execute the movements dictated by the control system.

Actuators are also responsible for the robot's speed and accuracy. If an actuator is too slow or imprecise, the robot won't be able to perform its tasks effectively. This is why choosing the right actuator is so important. It's not just about making the robot move—it's about making it move with precision.

The Real MVP: Control Systems

So, which is more important: sensors or actuators? The truth is, neither can function effectively without the other. Sensors provide the data, but actuators execute the movements. However, the real MVP in this equation is the control system. It's the brain that processes the sensor data and tells the actuators what to do. Without a good control system, even the best sensors and actuators won't be able to achieve precision.

Think of it like this: sensors are the scouts, gathering information from the battlefield. Actuators are the soldiers, carrying out the orders. But without a general (the control system) to process the information and give commands, the whole operation falls apart.

In modern robotics, control systems have become incredibly sophisticated. They use advanced algorithms to process sensor data in real-time and make split-second decisions. Some even incorporate machine learning, allowing robots to improve their precision over time. But no matter how advanced the control system is, it still relies on good data from sensors and precise movements from actuators.

Conclusion: A Delicate Balance

At the end of the day, precision in robotics is all about balance. Sensors and actuators both play crucial roles, but neither can do the job alone. It's the control system that brings everything together, processing the sensor data and telling the actuators how to move. So, the next time you see a robot performing a delicate task, remember: it's not just the sensors or the actuators that are responsible for its precision—it's the entire system working in harmony.

As one robotics expert put it, "Precision isn't just about having the best sensors or the strongest actuators. It's about how well they work together."