Hardware vs Software

Robots are often seen as the ultimate blend of hardware and software, but what if I told you that these two forces are constantly at war?

By Hannah White

When we think about robots, we tend to imagine sleek, futuristic machines that seamlessly blend hardware and software into one flawless system. The hardware is the body, and the software is the brain. Simple, right? Well, not so fast. The truth is, the relationship between a robot’s hardware and software is far more complex—and sometimes, downright adversarial.

On one hand, hardware is the physical foundation of any robot. It’s the motors, sensors, actuators, and the mechanical structure that allow the robot to move, sense, and interact with the world. Without solid hardware, even the most advanced software would be useless. On the other hand, software is what gives the robot its intelligence. It’s the algorithms, control systems, and decision-making processes that allow the robot to perform tasks autonomously. But here’s the kicker: these two elements are often in conflict.

Let’s break it down. Hardware is expensive and difficult to change. Once you’ve designed and built a robot’s physical structure, making significant modifications can be a logistical nightmare. Software, on the other hand, is far more flexible. You can tweak algorithms, update control systems, and even completely overhaul the robot’s decision-making processes with a few lines of code. This flexibility can create tension between hardware and software teams. Hardware engineers might feel constrained by the limitations of current technology, while software developers are constantly pushing for more advanced features that the hardware simply can’t support.

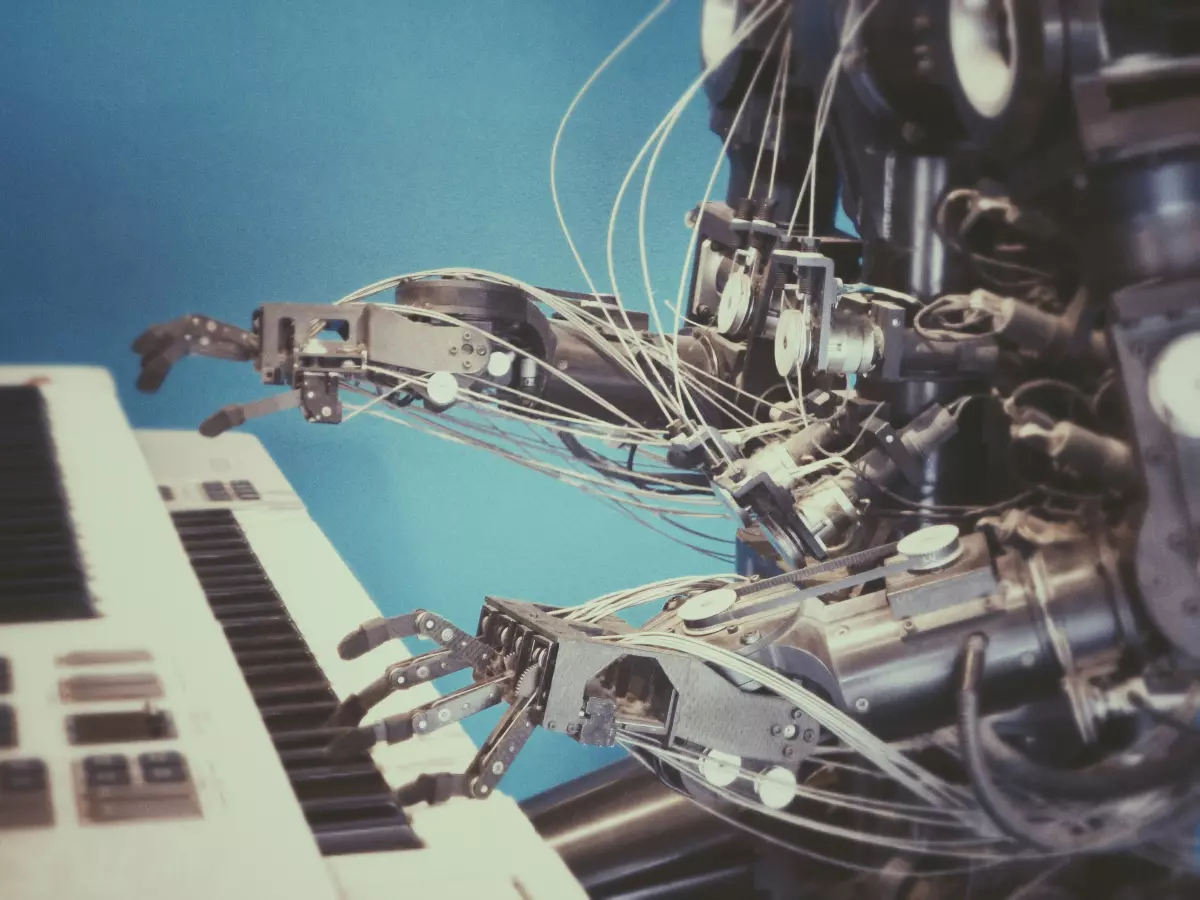

Take, for example, the issue of processing power. Many modern robots rely on advanced machine learning algorithms to make decisions in real-time. These algorithms require massive amounts of computational power, which means the hardware needs to include powerful processors and efficient cooling systems. However, adding more processing power increases the robot’s size, weight, and energy consumption—factors that can severely limit its mobility and battery life. It’s a classic case of software demanding more than the hardware can deliver.

But it’s not just about processing power. Sensors are another battleground in the hardware vs. software war. A robot’s sensors are its eyes and ears, allowing it to perceive the world around it. But sensors are far from perfect. They can be affected by environmental conditions like dust, moisture, and temperature fluctuations. Software developers often have to write complex algorithms to compensate for these limitations, which can slow down the robot’s decision-making process and reduce its overall efficiency. In this case, the hardware’s shortcomings force the software to work harder, creating a vicious cycle of inefficiency.

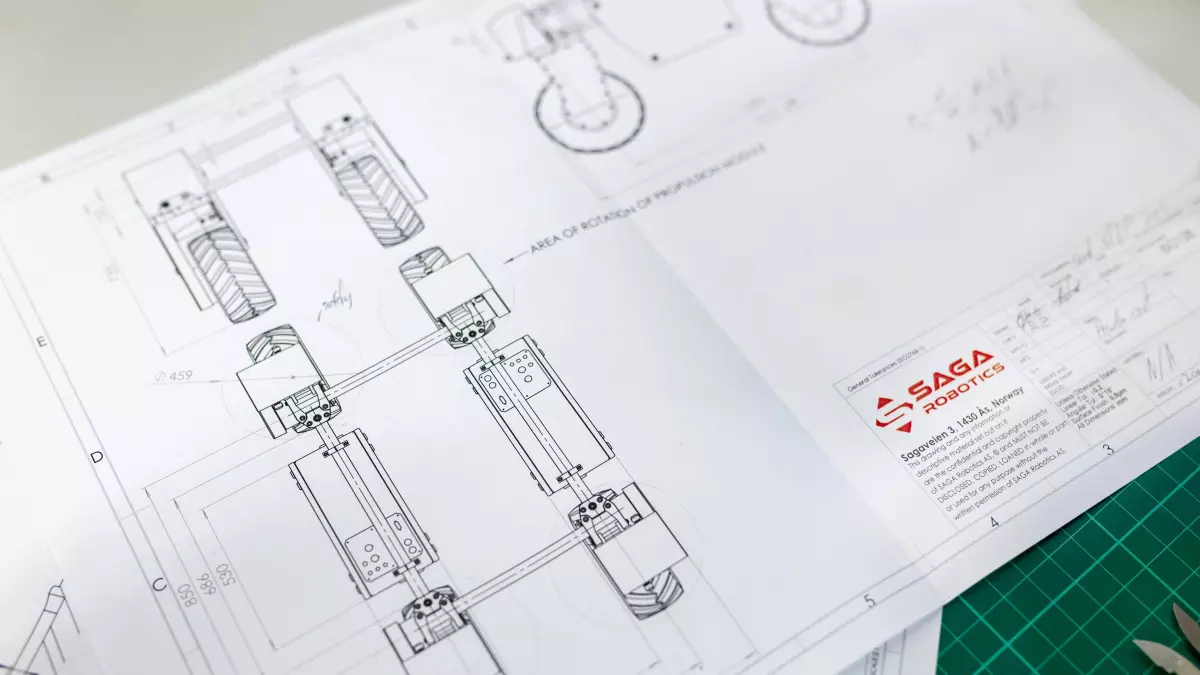

So, what’s the solution? How do we balance the needs of hardware and software in robotics? The key lies in collaboration. Hardware and software teams need to work together from the very beginning of the design process. Instead of treating hardware and software as separate entities, they should be viewed as two sides of the same coin. This means that hardware engineers need to have a deep understanding of the software’s requirements, and software developers need to be aware of the hardware’s limitations.

One approach that’s gaining traction in the robotics community is the concept of modular design. By designing robots with modular hardware and software components, engineers can create systems that are more flexible and adaptable. For example, instead of building a robot with a fixed set of sensors, engineers can design a modular sensor array that can be easily swapped out or upgraded as needed. Similarly, software can be designed in a modular fashion, allowing developers to add or remove features without having to rewrite the entire codebase. This approach not only makes it easier to balance the needs of hardware and software, but it also extends the robot’s lifespan by allowing for easier upgrades and maintenance.

Another promising solution is the use of real-time operating systems (RTOS). These specialized operating systems are designed to handle the unique demands of robotics, allowing hardware and software to work together more efficiently. RTOS can prioritize tasks based on their importance, ensuring that critical functions like motion control and sensor data processing are handled in real-time, while less important tasks like data logging are relegated to the background. This helps to reduce the strain on both the hardware and software, allowing the robot to operate more smoothly and efficiently.

Of course, no discussion of hardware vs. software would be complete without mentioning the role of artificial intelligence (AI). AI has the potential to bridge the gap between hardware and software by allowing robots to learn and adapt to their environment. For example, AI algorithms can be used to optimize a robot’s movements based on the limitations of its hardware, reducing wear and tear on mechanical components and extending the robot’s operational lifespan. Similarly, AI can be used to improve sensor accuracy by filtering out noise and compensating for environmental factors. In this way, AI acts as a mediator between hardware and software, helping to resolve conflicts and improve overall performance.

In the end, the battle between hardware and software in robotics is unlikely to be resolved anytime soon. As technology continues to evolve, new challenges will arise, and the tension between these two elements will persist. However, by fostering collaboration between hardware and software teams, embracing modular design, and leveraging the power of AI, we can create robots that are not only more capable but also more adaptable and efficient. The future of robotics depends on finding the right balance between hardware and software—and the sooner we achieve that balance, the sooner we’ll unlock the full potential of autonomous systems.

So, the next time you see a robot in action, remember: beneath that sleek exterior, there’s a battle raging between hardware and software. And while it may seem like a struggle, it’s this very conflict that drives innovation and pushes the boundaries of what robots can do.