AI in Manufacturing

Did you know that AI in manufacturing is expected to grow at a staggering 57.2% CAGR by 2027? That's right, AI is not just a buzzword anymore—it's a game-changer in the world of production.

By Hiroshi Tanaka

Manufacturing is one of the most complex and resource-intensive industries out there. Think about it: the sheer volume of materials, machines, and human labor involved is mind-boggling. But here's the kicker—AI is stepping in to streamline these processes, making production faster, cheaper, and more efficient. Whether it's predictive maintenance, quality control, or even supply chain optimization, AI is revolutionizing how we build things. And trust me, it's not just about robots on the assembly line anymore.

In this article, we'll dive deep into how AI is transforming the manufacturing industry. We'll explore the algorithms, frameworks, and real-world applications that are pushing the boundaries of what's possible. Ready to geek out? Let's go!

Predictive Maintenance: The AI Crystal Ball

One of the biggest challenges in manufacturing is equipment downtime. When a machine breaks down, it can halt an entire production line, costing companies thousands or even millions of dollars. Enter predictive maintenance, powered by AI algorithms. By analyzing data from sensors and historical performance, AI can predict when a machine is likely to fail before it actually does. This allows companies to perform maintenance at the right time, avoiding costly downtime.

Machine learning models like Random Forest and Support Vector Machines (SVM) are often used to detect anomalies in machine behavior. These algorithms can sift through mountains of data to find patterns that would be impossible for a human to detect. The result? Fewer breakdowns, lower maintenance costs, and a more efficient production process.

Quality Control: AI’s Eagle Eye

In traditional manufacturing, quality control is often a manual process. Workers inspect products for defects, which can be time-consuming and prone to human error. But AI is changing the game here too. With the help of computer vision and deep learning algorithms, AI can inspect products at a speed and accuracy that humans simply can't match.

Take, for example, convolutional neural networks (CNNs). These AI models are particularly good at image recognition, making them ideal for spotting defects in products. Whether it's a tiny crack in a car part or a misaligned component in an electronic device, AI can catch these issues before they become bigger problems. And the best part? AI systems can work 24/7 without getting tired or making mistakes.

Supply Chain Optimization: AI as the Master Planner

Supply chains are the lifeblood of manufacturing, but they're also incredibly complex. From sourcing raw materials to delivering finished products, there are countless moving parts that need to be coordinated. AI is stepping in to make this process more efficient by optimizing everything from inventory management to logistics.

AI algorithms like Linear Programming and Genetic Algorithms are being used to solve complex optimization problems in supply chains. These algorithms can analyze vast amounts of data to find the most efficient routes for shipping, the optimal levels of inventory to hold, and even the best suppliers to work with. The result? Faster delivery times, lower costs, and happier customers.

Robotics: The AI-Powered Workforce

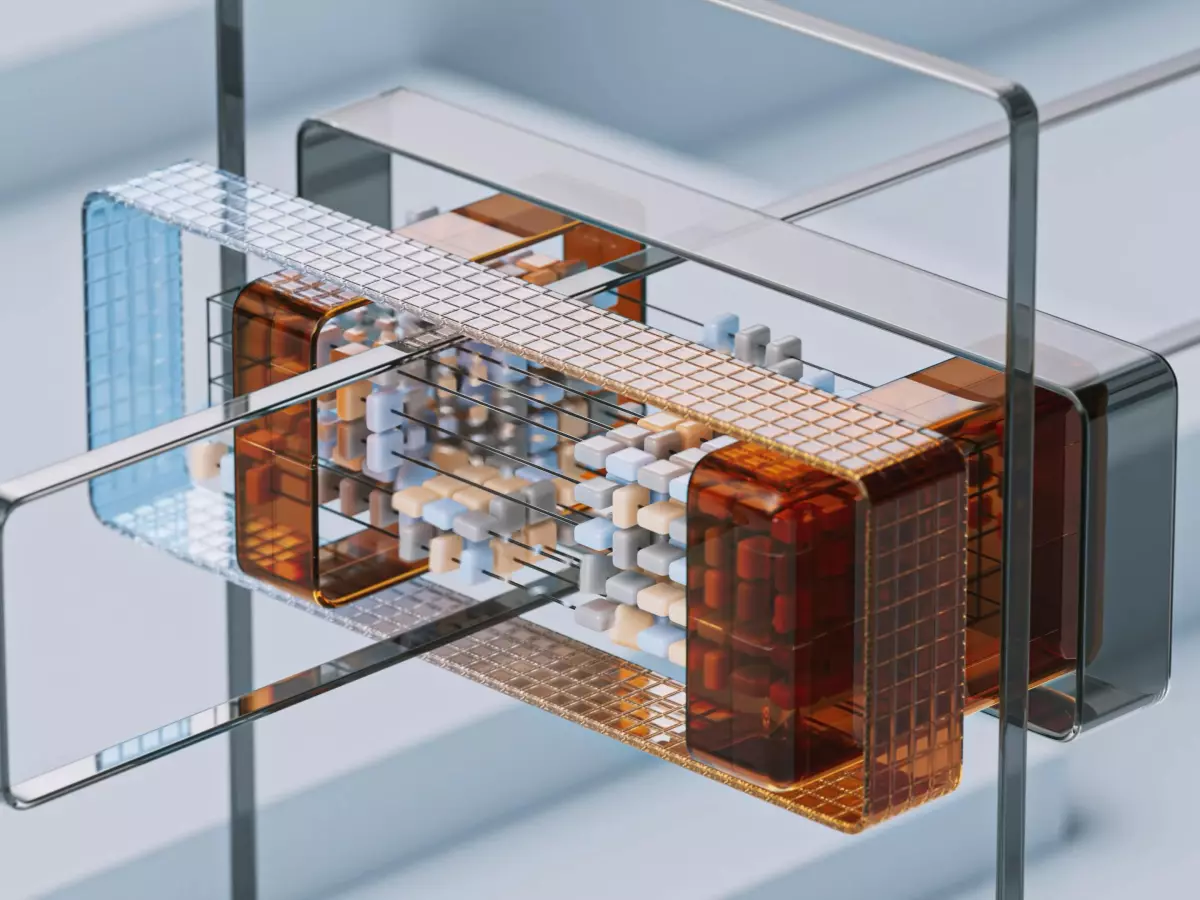

When most people think of AI in manufacturing, they picture robots on the assembly line. And while that's not the whole story, it's definitely a big part of it. AI-powered robots are becoming increasingly common in factories, where they can perform tasks like welding, painting, and even assembling complex products.

What's really exciting is the rise of collaborative robots, or "cobots." These robots are designed to work alongside humans, assisting them in tasks that require precision or strength. Powered by AI, cobots can adapt to their environment and learn from their human counterparts, making them incredibly versatile. And because they're equipped with sensors and AI algorithms, they can operate safely around humans without the risk of accidents.

AI Frameworks in Manufacturing

So, what frameworks are powering all this AI magic? Well, there are a few heavy hitters that are particularly popular in the manufacturing world. TensorFlow and PyTorch are two of the most widely used frameworks for building AI models. These open-source platforms offer a range of tools for developing machine learning algorithms, from neural networks to reinforcement learning models.

Another key player is Apache Spark, which is often used for big data processing in manufacturing. With its ability to handle massive datasets, Spark is ideal for analyzing sensor data, supply chain information, and other large-scale datasets that are common in manufacturing.

What’s Next for AI in Manufacturing?

So, where is all this heading? Well, the future of AI in manufacturing looks incredibly promising. As AI algorithms become more advanced and data becomes more accessible, we can expect even greater levels of automation and efficiency. Imagine a factory where machines can not only build products but also optimize their own performance in real-time. Sounds like science fiction, right? But with AI, it's closer than you think.

And it's not just about making things faster or cheaper. AI is also helping manufacturers become more sustainable by reducing waste and optimizing energy use. In a world that's increasingly focused on sustainability, this could be a game-changer.

So, whether you're a factory owner, an engineer, or just a tech enthusiast, now is the time to start paying attention to how AI is transforming manufacturing. Trust me, this is one revolution you don't want to miss.